Home

"Hammer Time!" - M C Hammer, 'U Can't Touch This'

Fatboy Hammer

Hammer Grip

I'm a fan of the early Star Treks, i.e. not a fan of the current Woke nonsense.

In the early series many new technologies were introduced amongst them was the replicator introduced in the Next Generation (24th cenury). As we are in the 21st century we don't have such a technology, however we do have a prequel to the replicator... in the form of the 3D printer.

I bought the Ender-3 V3 SE, mainly because it is cheap - coincidentally it is also well rated by everyone on Youtube.

The reason I bought it is this; since starting catapults, a few years ago, I have always wanted to make my own catapults, that way I could call myself a real catapultist and thereby make up for the fact that my aiming skills are poor compared to the real catapultists. You see a real catapultist makes his own catapults.

Traditionally a real catapultist whittles his catapult out of wood or plywood; others use steel or aluminium or some composite material, those of a cheap nature will use plastic as in HDPE or maybe polycarbonate. However the truly advanced 21st century catapultist uses a 3D printer, just like me.

It works like this;

-

Design the catapult in CAD or CG software, FreeCAD in my case or you could use Blender. Export the model in .stl (mesh) format.

-

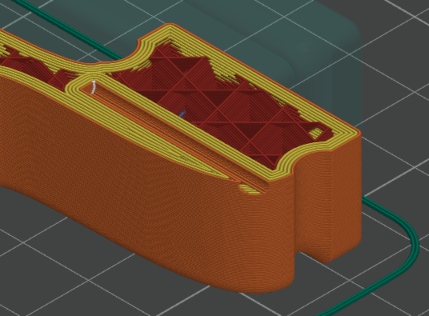

Import the .stl mesh and slice it (I use Orca Slicer) and export the results in .gcode (machine printing) format.

-

Upload the .gcode file to the 3D printer (Ender-3 V3 SE in my case) and print it.

Now I band it and fire it.

You might ask if there is any reason I don't just stick to my Hegarty H8-28, afterall I have often stated it is my favourite catapult.

Whilst it is a wonderful catapult, I am a Quality Engineer. Quality Engineers always want to improve upon a design even if it is 'perfect'.

The H8-28 uses a braced grip (the weakest grip). The hammer grip is the strongest grip (hence Jörg Sprave always uses a hammer grip with his stupidly powerful catapults). For some reason hammer grip catapults are not that numerous compared with braced or pinch grip catapults. A pinch grip catapult is similar to a fat hammer grip, hence my current heavy set-up is on the Hegarty SS4 OTT.

I therefore designed the Fatboy with a hammer grip, because if the grip is strong it will feel light and therefore easier to control and therefore be more accurate. Spanish style target catapults are hammer grip with a fat/brace style grip at the top and have very light bands. To further enhance the strength of the grip (or alternately the lightness of the grip at a particular band strength) I've kept the forks as low as possible, i.e. as close as possible to the hand to minimise leverage. I could get it closer but then the ammunition would hit the hand...

Note that TTF catapults come in Hammer and Pinch styles but not braced styles. Braced style are the weakest grip and a TTF cannot get closer than half a band width from the hand.

Why is the catapult so fat... because a hammer grip is basically a pistol grip and a pistol grip is longer in the direction of the target, hence the Fatboy handle is 30 mm long in the direction of the target and 20 mm wide. Hence the entire catapult is 30 mm thick for ease of printing and design.

You might at this point ask why the hammer handle isn't angle like a pistol grip, i.e. a pistol grip is not at right angles on a pistol, it is instead typically angled at around 20° from vertical.

Well the Fatboy handle is angled. As I press the catapult out against the elastic tension I just let the catapult angle itself into a 'pistol' grip. The leading edge of the forks is parallel to the target but that doesn't mean the target face of the forks needs to be parallel to the target...

And so you have it, the picture at top is the latest design - I'm still tweaking the CAD design further and improving the slicer settings following the Quality Engineer's credo of continuous improvement...

24th August 2024